Z type bucket elevator

ZType bucket elevatorfeatures

1.The frame is eversion type, the interior is not easy to hide dirt

2.Made of 304 stainless steel, the whole machine can be washed, safe and sanitary.

3.Can be made of single or multiple feeding port.

4.The hopper is made of food grade plastic polypropylene.

5.Can be customized according to the required size, hopper capacity of 1L/1.8L/4L/6L.

6.All parts have easy to remove inspection cover and easy to check the door, the hopper is easy to install and disassemble.

7.The automatic feeding and stopping function is realized by the control circuit and the level control.

Equipment advantage

Equipment quality

Fully enclosed 304 stainless steel frame, door and cover plate

Precision manufacturing using the most advanced laser cutting technology

Continuous sputtered TIG welds throughout the entire process

versatility

Feed multiple inline packaging machines with a single bucket elevator

Feed multiple feed points into one packing machine

For processing or packaging applications

Gentle lifting and conveying

Before applying to finished product packaging

Minimal yield degradation

Product filling area chain bucket design, no sanitary dead

AngleFeed and discharge transition to ensure gentle, uniform feed

Innovative design

Small occupation area, saving valuable factory space

Custom designed and built to meet specific project needs

Custom controls integrate various devices

Transition chute, vibrating feeder and storage hopper

A Z-type bucket elevator equipment to meet the needs of multi-bin feeding, saving customer equipment procurement costs

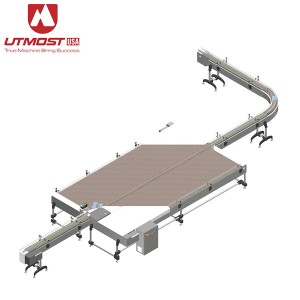

Layout

Parameters

| Model | 1.0LBucket elevator | 1.8LBucket elevator | 3.8LBucket elevator | 6LBucket elevator |

| Speed | 2-3.5t/h | 4-6t/h | 6.5-8t/h | 7.5-11/h |

| Machine high | Tailor it to your needs | |||

| Feed hole high | Tailor it to your needs | |||

| Material | Food grade PP/304 | |||

| Voltage | AC single phase 220V/AC Three phase 380V,50HZ/60HZ | |||

| Power | 0.75-2.2kw | |||