UTMOST A117 Round Jar Labeller

Overview

This is an intermittent motion round bottle labeling machine featuring mold-based precision positioning and servo-driven label feeding. Equipped with high-accuracy photoelectric detection, it delivers stable performance at speeds ranging from 20 to 120 bottles per minute (depending on container size). The machine boasts a simple and compact design with easy size changeover capability, making it ideal for flexible production requirements.

Parameters:

| Model: | A117 |

| Production Capacity: | 20-120labels/min |

| Packaging Container: | Jar, Tin, Can, Bottle Etc |

| Container Size: | Diameter 20-100mm |

| Label length | 10-200mm |

| Precison | +-0.5mm |

| Voltage: | Single Phase, 220V,50/60HZ |

| Power Consumption: | 1.3KW |

| Machine Dimensions: | 1800×1100×1450mm |

| Weight: | 350KG |

Advantages

Precision Registration: Special sensor detects bottle orientation features for accurate alignment.

Accuracy position: 3-point holding ensures precise bottle positioning during rotation.

Flexible Handling: easy for different round size by change mould

Centralized Management: Integrated control panel displays peripheral device parameters and alarms.

Smooth Operation: Servo motor-controlled label feeding ensures precise and reliable performance.

User-Friendly Design: Compact layout with easy access for troubleshooting and maintenance.

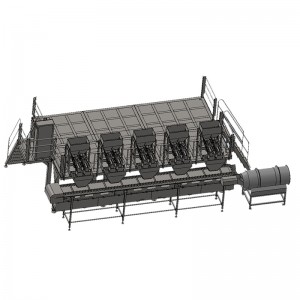

Layout