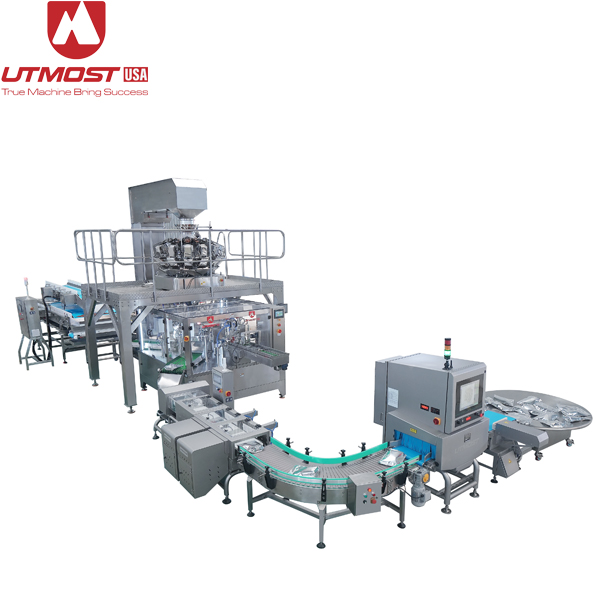

Pecan premade pouch packaging machine

RP8250/300ZG series packaging machine is specially designed for granular materials, the whole machine is operated by one key through PLC touch control and frequency conversion speed control, the bag opening mechanism designed for the bag opening characteristics ensures high bag opening rate, the empty bag is automatically rejected to save consumables, and the 8 sets of machine clamps are synchronously adjusted by one key for quick changeover. The whole machine 304 stainless steel contact parts with oil-free vacuum pump, the table can be rinsed and easy to clean, to meet the food grade hygiene standards.

| Model number | UTMS-14 |

| Maximum weighing capacity | 100-2000g |

| Weighing accuracy range | 0.1-5g |

| Maximum weighing speed | 70Fill/minute |

| Hopper volume | 2500ml |

| Control panel | 10.4-inch touchscreen |

| Drive system | stepper motor |

| Power | 220V / 1500W / 50/60hz / 10A |

| Package Size | 1750(L)x1200(W)x12400(H) |

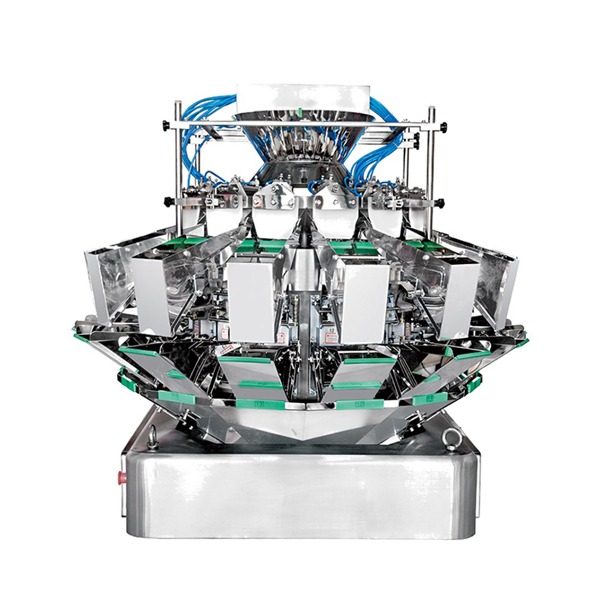

14 Head Shatterproof Combination Scale

The Multihead Scale Anti-Breakage Combination Scale uses an inclined weighing hopper that shortens the drop height in advance to protect the integrity of the weighed material. Suitable for weighing fresh fruit, ice, biscuits, peanuts and other fragile materials.

| Model number | UTMS-14 |

| Maximum weighing capacity | 100-2000g |

| Weighing accuracy range | 0.1-5g |

| Maximum weighing speed | 70Fill/minute |

| Hopper volume | 2500ml |

| Control panel | 10.4-inch touchscreen |

| Drive system | stepper motor |

| Power | 220V / 1500W / 50/60hz / 10A |

| Package Size | 1750(L)x1200(W)x12400(H) |

Z type bucket elevator

The Z-bucket elevator is specially designed to lift materials vertically and transport them horizontally in confined spaces. It efficiently connects equipment of different heights and orientations via a unique 'Z'-shaped sealing path. The core value lies in significantly saving valuable space, reducing dust contamination and ensuring the directional, clean flow of granules, powders and small pieces of material. This optimises layout, reduces wastage and improves the safety and cleanliness of the production environment.

| Product Parameter | |

| Model number | UTBE-10 |

| Production Capacities | 10m³/hours |

| Elevation Height | Up to 5000mm |

| Chain material | stainless steels |

| Hopper material | PP |

| Frame material | stainless steels |

| Power supply | 220v, 50/60hz, 3ph |

| Power (output) | 0.75Kw |

| weights | 180kg |

Metal & Weight Checker

The equipment integrates high sensitivity metal detection and accurate weight detection functions, adopts internationally renowned hardware and adaptive algorithms, and all operations are completed through a single touch-screen interface, which significantly simplifies the process, reduces the risk of operational errors, and improves inspection efficiency and reliability.

| Product Parameter | |

| Main material | 304stainless steels |

| Weighing range | 10~4000g |

| Minimum scale | 0.1g |

| Maximum detection accuracy | ±0.5g |

| Maximum throughput | 150piece/minute |

| Metering belt specification (L*W) | 300*550mm |

| Conveyor belt height above ground | 750-850mm |

| power requirement | AC220V,50 - 60Hz |

X-ray foreign object detector

It is designed for small and medium-sized packaged products in the food, pharmaceutical and chemical industries, and is not affected by temperature, humidity, salt or aluminium foil packaging, and is characterised by high precision and reliability.

| model number | ZS20 - XD - C4016 - SE |

| radiation source | 80kV,max: 210W |

| operating system | Linux(kernel version 4.10) |

| control panel | 17-inch touchscreen LCD |

| Conveying speed | 5 - 60 metres/minute |

| Weight to be measured | max 10kg |

| Size to be measured | Maximum width 400mm, maximum height 160mm |

| power supply | AC220V,50 - 60Hz |

| temperature and humidity | Ambient temperature 0 - 45 degrees Celsius Relative humidity 30 - 85% Non-condensing |

| waterproof rating | IP66 for conveyor, IP40 for other parts |

| equipment material | Full mirror finish 304 stainless steel |

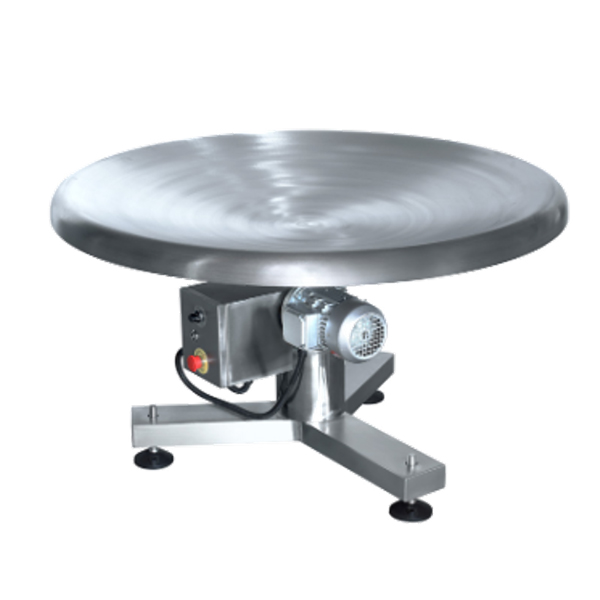

Disc stocker

The equipment is usually used to collect the completed packaging materials, so that they are neatly arranged and waiting for subsequent packaging operations, often connected with the finished product conveyor or other conveyor lines; its main structure is made of safe and hygienic 304 stainless steel, according to the actual intensity of labour and flexible adjustment of the rotational speed in order to optimize the operation; the whole machine is easy to install and dismantle and easy to clean thoroughly, to protect the health and convenience of the maintenance.

| Technical parameters | |

| Model No. | YP-1200 |

| Diameter | 1200MM |

| Discharge height | Customised on demand |

| Material | Food grade 304 stainless steel |

| Speed control method | converter |

| Input voltage | three-phase220V/AC 50HZ/60HZ |

| Power (output) | 0.37kw |